The design and manufacture of gears for multipliers in our company began in 1985. To date, more than 400 products, which are multipliers and gearboxes with a center distance from 225 to 500 mm have been produced. These gear drives are successfully used as part of pumping units at nuclear power plants, in turbo-compressor packages and power plants.

The specialists of our company have all the necessary competencies for the complex solution of issues on the manufacture of gears, with the provision of the necessary technological process, the required productivity and quality.

Cutting of a gear and cutting of splines into a part is carried out on high-tech equipment in the Company. All this allows to manufacture any part required by the customer with the specified parameters in the shortest possible time. At the same time, the quality of the products always remains maximum. Especially this approach to work is convenient and beneficial if you need to fulfill a large order of the same type of parts. In this case, the cost of each unit becomes minimal, which is beneficial for the client, as it helps to reduce the cost of the entire batch of the order.

The unique machine tool park of gear-cutting equipment numbers 44 items and allows to fulfill processing of various materials – metals and alloys, plastic and multilayer materials.

Reliable operation of the gear train is ensured by high requirements for the precision of gear manufacturing. The power of sound energy during the operation of the gear transmission is in direct proportion to the error in the shape of the surface profile of the mating gears.

The value of the profile deviation is expressed as a deviation of the tolerance for the accumulated step error, the tolerance for the profile error, the tolerance for the direction of the gears, as well as the diagram of the longitudinal and transverse correction of the gears profile.

Finishing of gears in our plant is carried out on a HÖFLER gear grinding machine, with the possibility of monitoring all of the above parameters using a Renishaw contact measuring system.

OUR MANUFACTURING CAPABILITIES

Spur helical gears milling

Мах. module — 20; Мах. cut diameter D 1600 mm; length — up to 600 mm;

Involute splines (external splines) milling

Мах. module — 12; Мах. cut diameter D 400 mm; length – 3500 mm

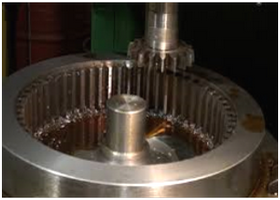

Internal spur gears shaping

Мах. module — 10; Мах. cut diameter – D800 mm; Мах. width of the rings to be cut — 180 mm;

Straight and circular bevel gear cutting

Мах. module — 8; Мах. cut diameter – D450 mm.

Spur helical gears grinding

Мах. module — 35; Мах. diameter D 1250 mm; length — up to 1000 mm.

Brief machine characteristics | Gear milling machines | Gear shaping | Gear grinding | |||

| Vertical medium prec. | Vertical high prec. | Horizontal | Increased prec. | High prec. | ||

Module | 1…20 | 2…16 | 1…12 | 1…10 | 0.5…8 | 2…18 |

| Machining diameter, mm | 60…2 000 | 100…1 500 | 60…400 | 30…800 | 10…300 | 100…1 200 |

Machining length, mm | up to 600 | up to 600 | up to 3 500 | up to 180 | up to 170 | up to 600 |

Tilt, deg | +/- 45 | +/- 35 | +/- 45 | +/- 0 | +/- 30 | +/- 30 |

Accuracy degree | 8 | 5 | 8 | 8 | 6…7 | 5 |