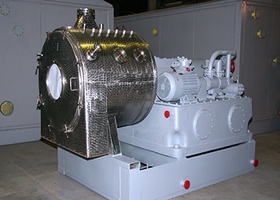

At present Jthe Company produces nearly all centrifuge types known in the world engineering, including modern heavy-duty automatic centrifuges with continuous cycle, high-speed tubular centrifuges, etc.

Depending on the purpose, centrifuges can be made of carbon and stainless steels, as well as titanium alloys.

Depending on technological purpose the Company manufactures the centrifuges of FGN and OGN types.

Filtering centrifuges (FGN type) are designed for separation of suspensions with solid phase having crystalline structure or granular structure with particle size of 30-150 µm.

Settling centrifuges (ОGN type) are designed for separation of difficult-to-filter suspensions with medium and fine grain (particle size of 5 … 40 µm), when high content of liquid phase in received sediment is allowed, and use of filtering surfaces is impossible.

The advantages of these centrifuges are the follow¬ing: simple design, automatic control, and possibility for processing suspensions of wide range of solid phase concentration and particle sizes, high quality of solid phase washing (FGN-type centrifuges).

This equipment can be operated in explosion-hazardous premises of B-la, B-lla class, as well as in the rooms with increased humidity.

In centrifuges the blade cuts the sediment at low basket rotational speed, in consequence of which the crushing of sediment crystals is practically excluded.

The centrifuges are equipped with the device for steaming of centrifuge casing internal surface and basket external surface. When filtering centrifuges operation suspension is supplied from above at low (compare with working) basket rotational speed. Then the speed is brought up to maximum, at which the sediment is pressed out, washed and repressed. The sediment is discharged by the blade at low basket rotational speed.

The centrifuges with clarifying bowl are used for clarification of suspensions containing no more than 1% of highly refined solid phase (oil, albuminous suspension, culture liquid, blood protein).

The centrifuges with separating bowl are used for separation of stable emulsions (separation of water from transformer oil or different greases).

When separating of emulsions the centrifuges operate continuously, when batch separating of suspensions, the centrifuges are required to be stopped periodically for bowl cleaning.

They are also used for separation of suspensions with medium abrasive solid phase basically consisting of crystalline products (ammonium sulphate, copper sulphate, copper vitriol, sodium chloride, sodium nitrate, potash, carbamide, alum, sodium sulphate), short-fibered materials (acetyl and ethyl cellulose, nitrocellulose) and amorphous products.

This type centrifuges are widely used in chemical, metallurgical, metal mining, sugar industries and other branches of industry.

The advantages of this type centrifuges are the following: design compactness, easy of service, continuity of production process of suspension separation, possibility of sediment washing, high degree of drying, high efficiency, possibility to connect to automatic or continuous-action production lines.

When ordering the equipment which is been interested in, please fill in the Questionnaire.