Manufacturing new equipment for the gas and oil industry is a priority for “SMNPO –Engineering” JSC and obliges the manufacturer to pay special attention to the reliability and quality of products, which is impossible without extensive testing. In order to carry out string and simulation tests, experimental and engineering development turbo-compressor packages prototypes, development new solutions for the design documentation, the scientific testing complex has been created at JSC.

The scientific- testing complex includes string test facilities of the test bench unit and research facilities of the experimental production workshop.

The test bench unit includes:

The facilities include the following equipment :

– closed gas loop

– gas coolers

– control valves

– flow meters

– gas loop charging compressor

– the system of gas loop purging with inert gas

– oil system

– start-up and fuel gas treatment system

The facilities are controlled remotely using an automatic control system (ACS).

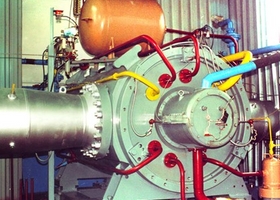

The facilities are designed to test turbo-compressor packages. The facilities include the following equipment:

The facilities are designed to test turbo-compressor packages. The facilities include the following equipment:– closed gas loop

– gas coolers

– control valves

– flow meters

– gas loop charging compressor

– oil system

– start-up and fuel gas treatment system

The facilities are controlled remotely using an automatic control system (ACS).

The facilities are designed to carry out natural gas test of centrifugal compressors different models and removable rotor bundles (RRB) of 6.3…16 MW power with both right and left direction of shaft rotation.

Facilities parameters

| Parameter description | Value | |

| 1 | Compressor rotor speed, rpm | 3750-8500 |

| 2 | Rated power on the gas turbine coupling (kW, min) | 16000 |

| 3 | Fuel gas flowrate at 1600 kW power (kg/s) | 1.21 |

| 4 | Fuel gas pressure, MPa | 2.45 ± 0.25 |

| 5 | Fuel gas temperature, °С | 20 ¸ 60 |

| 6 | Compressor gas discharge pressure, MPa, max | 10.0 |

| 7 | Loop max capacity, m3/min | 600 |

| 8 | Process gas temperature, °С, max | 90 |

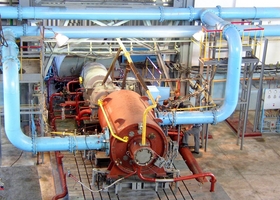

The facilities are designed to carry out mechanical and gas dynamic testing compressors of 6,3 MW and 16 (25) MW power with air and model gas according to API-617 and ASME PTC 10.

The facilities include driving motors, fluid couplings, gear box, oil and sealing system, air ducts, control valves, automatic control system (ACS), information and measuring system (IMS).

The facilities are designed to carry out aerodynamic tests of axial fans impellers for ACU of 2800 mm and 4500 mm diameter.

The facilities are designed to carry out aerodynamic tests of axial fans impellers for ACU of 2800 mm and 4500 mm diameter.

The facilities are designed to carry out testing piston compressor units and compressor cooling equipment with air and natural gas.

The facilities are designed to carry out testing piston compressor units and compressor cooling equipment with air and natural gas.

Facilities parameters

| Parameter description | Value |

| Suction gas pressure | 55 kgf/cm2 |

| Discharge gas pressure | 250 kgf/cm2 |

| Loopt capacity | 8000 nm3/h |

The facilities are designed to test NGV Gas Stations manufactured by “SMNPO –Engineering” JSC.

NGV Gas Stations АGNKS-125 during testing

Facilities parameters

| Parameter description | Value |

| Station suction gas pressure | 0…16 kgf/cm2 |

| Station discharge gas pressure | 250 kgf/cm2 |

| Circuit capacity | 8000 nm3/h |

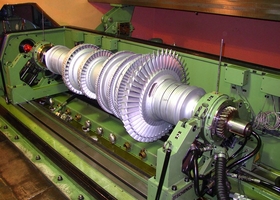

The facilities are designed to carry out rotors dynamic field balancing at operating speed.

The facilities are designed to carry out rotors dynamic field balancing at operating speed.Schenk test facilities for balancing centrifugal compressors rotor.

Facilities parameters

| Parameter description | Value |

| 1.Speed, rpm | 0 … 40000 |

| 2. Rotor weight, kg, max | 2500 |

| 3. Impeller diameter, mm, max | 1100 |

| 4.Vacuum level, kgf /cm2 | 0.002 |

Experimental research facilities are located in the experimental production workshop:

The facilities are designed to research the model stages of centrifugal compressors.

Work objective:

– development the centrifugal stages design to increase their polytropic efficiency up to the level of 85-87% and provide possibly to a greater flatness of gas-dynamic characteristics in the operating modes area;

– checking calculation methods of stages design.

These are the facilities for static blowdown based on a TV-80-1.4 turbo blower driven by a 3-phase asynchronous electric motor of 100 kW power.

The facilities are designed to purge stationary elements of the turbomachines flow path, turbo-compressor packages (GPA) suction and exhaust systems.

The facilities are designed to purge stationary elements of the turbomachines flow path, turbo-compressor packages (GPA) suction and exhaust systems.

Work objective:

– increasing the efficiency of the compressor rotor bundle by improving the characteristics of suction and collection chambers, suction and discharge branch pipes;

– decreasing pressure losses in the GPA suction and exhaust systems and increasing the effective drive power;

– purging Air Cleaning Unit components (filter cartridges, fabric bags) to plot their characteristics and make reasonable choice of filter materials;

– purging various types separator models to optimize their geometric characteristics and reduce material consumption.

DGS facilities are driven by 90 kW power DC motor.

DGS facilities are driven by 90 kW power DC motor.

The facilities are designed to research, test and develop DGS for centrifugal compressors.

Work objective:

– DGS testing for manufactured compressors to confirm their performance at string test pressure levels;

– researching new types of DGS to introduce them into advanced compressor designs;

– testing new types of the friction pair materials and coatings to increase reliability of their operation and reduce the friction pair subassembly cost.

These are the facilities for oil end seals, oil shoe and pad bearings and low-flow mechanical seals driven by 300 kW power DC motor.

The facilities are designed to research, test and develop the oil system elements and seals.

Work objective:

– development seal design with floating rings to reduce oil migrating into the rotor bundle (non-recoverable loss of oil);

– development DGS advanced designs with reduced oil losses, including impulse-type end seals.

The facilities are designed to research and develop the cycle and structural elements of reciprocating compressors.

The facilities are designed to research and develop the cycle and structural elements of reciprocating compressors.

Work objective:

– life tests of valves and seals to increase their durability;

– increasing the speed of the basic compressor components, which will provide decreasing the specific material consumption

– creating monitoring and diagnostic systems, which will increase the compressor performance

The facilities are designed to research and demonstrate the capabilities of the electromagnetic bearing.

Work objective:

– determining the characteristics of the electromagnetic bearing as well as their control system;

– testing magnetic bearing in the manufactured compressors and setting control systems to reduce the time of pre-commissioning;

– development algorithms and programs to control the electromagnetic bearing.

The facilities are used to test vortex compressors designed for delivery separation air to electromagnetic bearings of centrifugal compressors.

The facilities are used to test vortex compressors designed for delivery separation air to electromagnetic bearings of centrifugal compressors.

Work objective:

– testing serial vortex compressors;

– testing and development advanced designs of vortex machines;

– checking solutions to improve the compressors efficiency.

The facilities are designed to obtain experimental flow characteristics of valves.

Work objective:

– creating competitive valves with characteristics meeting modern standards

The facilities are designed to test ball valves of DN50 to DN200 size at temperatures from -70°С up to +400°С.

The facilities are designed to test ball valves of DN50 to DN200 size at temperatures from -70°С up to +400°С.

Work objective:

– creating competitive valves with characteristics meeting modern standards.

The facilities are designed for the experimental determination of the impellers natural vibration frequencies.

The facilities are designed for the experimental determination of the impellers natural vibration frequencies.

Work objective:

– improve the reliability of centrifugal compressors performance by pre-tuning the resonant frequencies;

– exclude cases of impellers destruction during operation

The facilities are designed to carry out air mechanical and gas-dynamic tests of centrifugal compressors of 16 (25) MW power.

The facilities are designed to carry out air mechanical and gas-dynamic tests of centrifugal compressors of 16 (25) MW power.

Work objective:

– checking manufacturing and assembling quality;

– checking proper running of separate assembly units and their interaction in operating condition;

– checking gas dynamic parameters meeting engineering documentation requirements.

The facilities are designed to develop the new elements of “gas-gas” pressure differential regulator

The facilities are designed to develop the new elements of “gas-gas” pressure differential regulator